HIGH DENSITY POLYETHYLENE (HDPE) PIPE AND FITTINGS

Polyethylene Pipe (PE Pipe), or poly pressure pipe as it is commonly known, is a commonly used piping system for fluids and gasses throughout India. Polyethylene’s toughness, immunity from corrosion, excellent resistance to chemicals and low weight have contributed to its continued appeal for use in situations where cost-effective and reliable piping systems are required.

Presvels Pipe Systems manufactures robust high-performance polyethylene pressure pipes for a wide range of applications. Because PE pressure pipe is so flexible and workable, it is used across many different industries, including mining, plumbing & drainage, infrastructure projects, industrial process plants, HVAC, irrigation & rural farming, and communications and power conduits.

Presvels manufactures HDPE pressure pipes designed specifically for the following systems:

Presvels-Water (drinking water pipeline)

Presvels-Fire (fire main pipeline)

Presvels -Gas (gas pipeline)

Presvels -Therm (above ground pipeline)

Presvels -Drain (wastewater pipeline)

Presvels -Power (electrical conduit)

Presvels -Rural (imperial pipe for rural areas)

Presvels -Black (UV-resistant PE100 pipeline)

Presvels -Comms (communications conduit)

Presvels -Tech (recycled water pipeline)

Presvels -Sewer (sewer pipeline)

Presvels -Tech PP-R (sanitary & HVAC PP-R system)

Presvels -Fab (poly fabrication services)

Presvels -Subduct (conduit inner subduct)

Presvels -Air (blue jacket compressed air pipe)

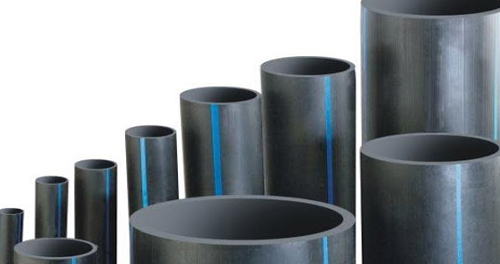

POLYETHYLENE PRESSURE PIPE (PE) HD-PE100

Presvels -Tech’s large diameter coiled HDPE pipe is strapped in layers, so the poly pipe coil does not dangerously unwind, as some vinidex pipes or iplex pipes are prone to do. HDPE poly pressure pipe can be joined by a variety of methods, including electrofusion fittings, compression fittings, butt weld/short spigot fittings, HDPE transition fittings and BSP threaded adaptor fittings.

THE PRESVELS -TECH DIFFERENCE

Failure occurs when the molecules reach their breaking strain or when test sample defects, such as edge nicks, begin to grow and cause failure. Fibrillation, the stretching and tearing of the polymer structure, usually occurs just prior to rupture. Tensile or compressive elastic deformations of a test specimen along a longitudinal axis excite respective inward or outward deformations parallel to a transverse axis normal to the first. Poission’s ratio is the ratio of lateral strain to longitudinal strain. When tested according to ASTM E 132, Standard Test Method for Poisson’s Ratio at Room Temperature, Poisson’s ratio for polyethylene is between 0.40 and 0.45.

Manufacture

Quality Assurance- Poly Pipe WA

Poly pipe sizes / dimensions are as follows:

- Size / Diameter : 20 to 630mm

- Length of Pipe : 6.0 Meter

- Usage / Application : Water Supply

- Colour : Black

- Brand : Presvels

- Material : HDPE

- Pressure : 2.5 to 20 kg/cm2

Features and Specifications

- Manufactured from virgin pipe grade raw materials (PE80, PE100).

- Excellent corrosion and chemical resistance. Inert to most acidic and alkaline solutions.

- High flow characteristics.

- Light in Weight.

- Easy to handle & transport.

- Excellent flexibility combined with strength.

- Smooth inner walls minimises frictional losses.

- Safe for potable water supply.

- Manufactured as per IS-4984, ISO-4427

- Manufactured from 20 to 2500 mm sizes at various pressures.

- Upto 6" in straight lengths and coils. Higher sizes in standard and other straight lengths only.

- Very good adoption of earth movements.

Applications:

- Lift and gravity water supply systems.

- Micro & sprinkler irrigation systems.

- Sewerage pumping and effluent disposal systems.

- Column pipes for submersible pumps.